¶ About This Manual

Welcome to Revopoint Measurement Software User Manual! This manual provides operational guidelines and instructions for the Revo Measure software. You can quickly jump to the corresponding section by clicking any title in the navigation bar.

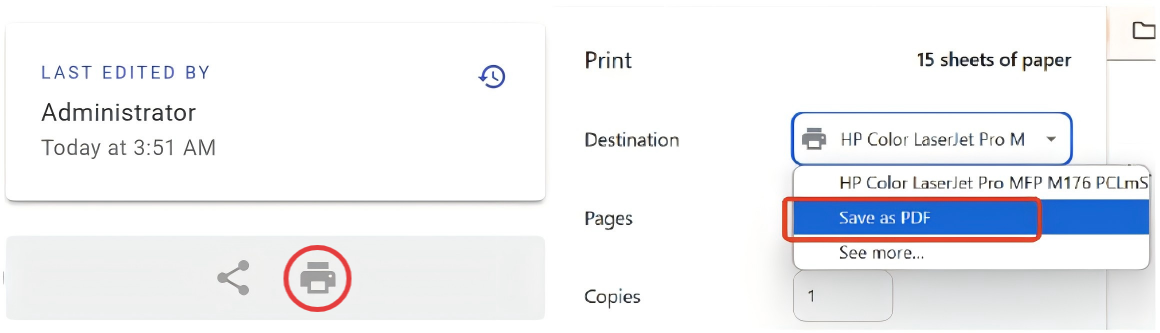

Manual Download

If you need a PDF manual, click the Print Format button at the bottom of the navigation bar on the left side of the manual, and select "Save as PDF" from the options.

Note: The software will be continuously updated. The content of this manual and specific operations are for reference only. Please refer to the actual software interface for details.

¶ Software Activation

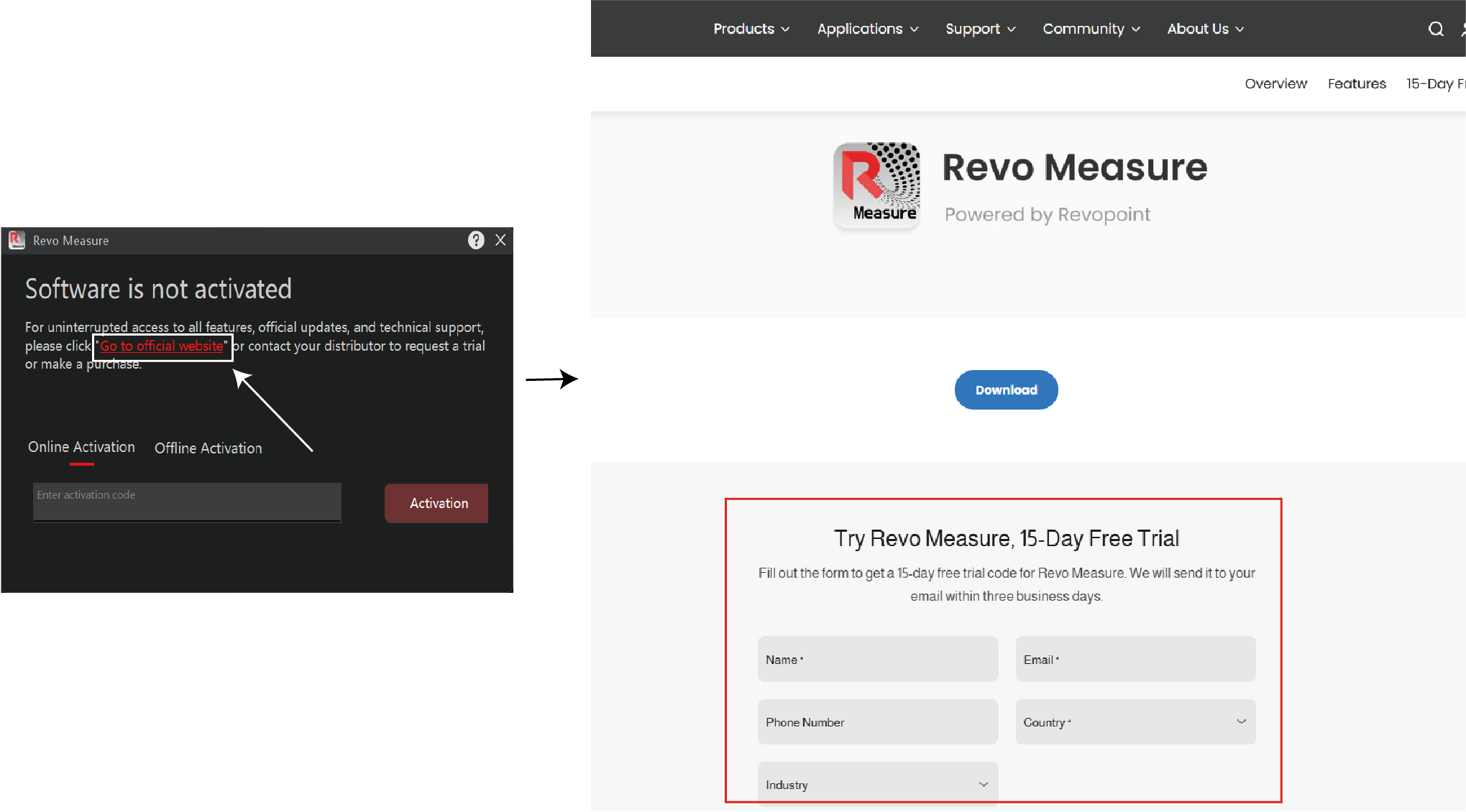

¶ Trial Software Activation (Online Only)

① Visit Revopoint's official website and go to "Support – Download" to download the Revo Measure software.

② Open the software. In the activation pop-up window, click "Go to official website" to enter the Revo Measure software page and apply for a trial.

③ The trial license code will be sent to the email address you provided when applying for a trial.

¶ Purchased Software Activation

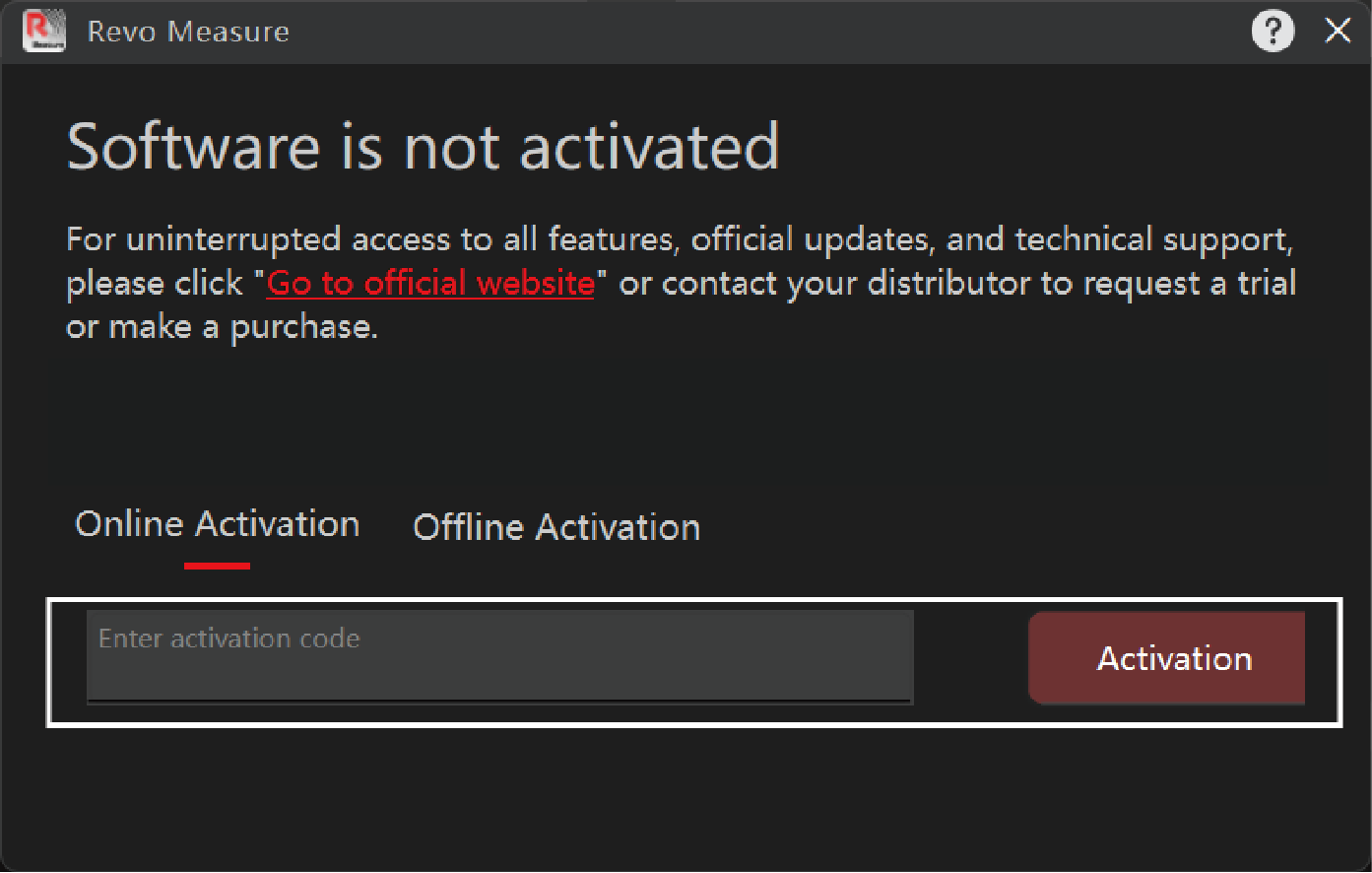

¶ Online Activation (*Recommended)

① Obtain the Activation Code

The activation code will be sent to the email address provided when you take an order.

Note: One activation code can only be bound to one single computer. If you don't receive the activation code, please contact official customer support for assistance.

② Activate the Software

Open the software.In the activation pop-up window, select "Online Activation." Ensure the network connection is stable, enter the activation code, and click "Activate."

Note: If the activation fails, please contact our official customer support for assistance.

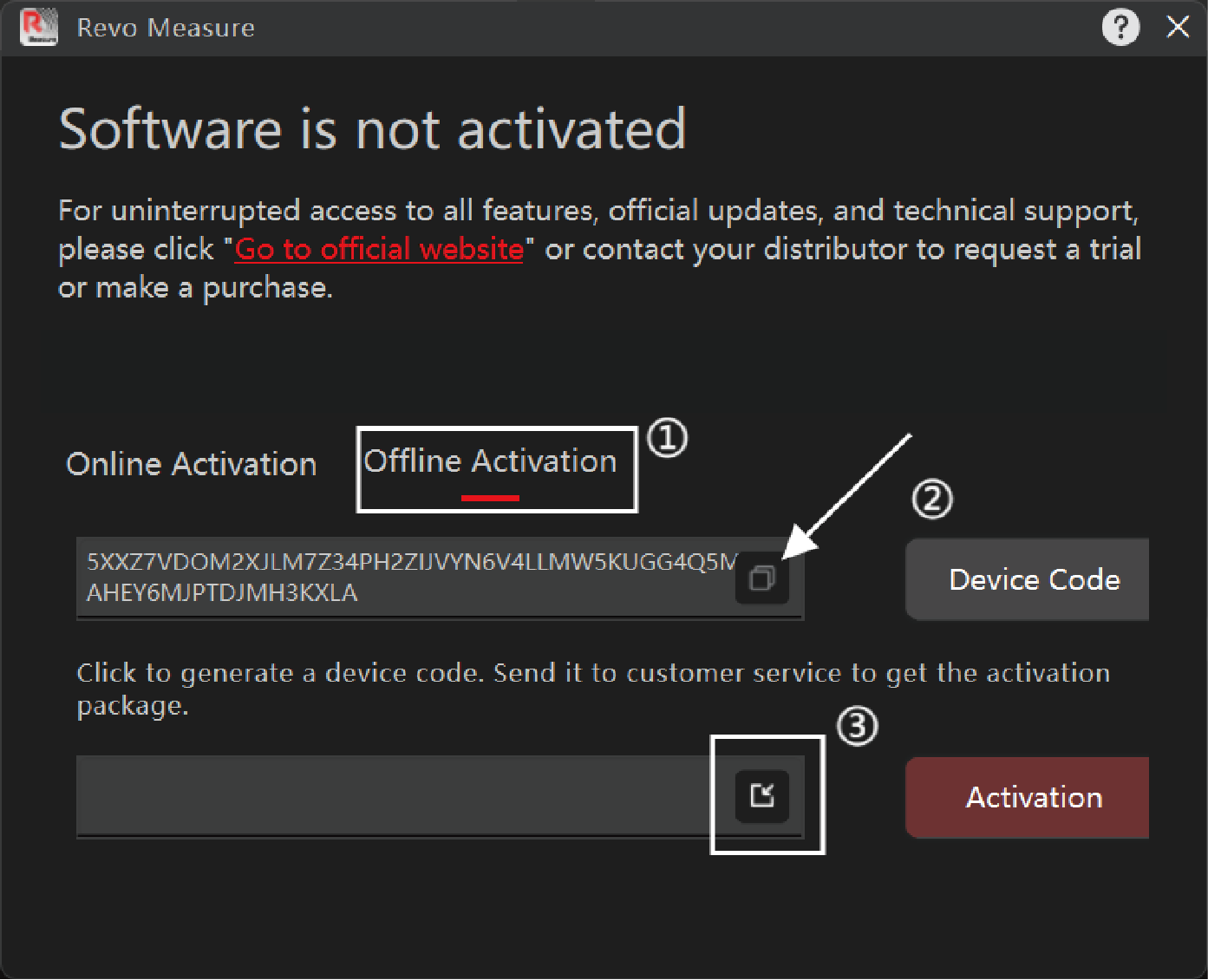

¶ Offline Activation

Offline Activation is suitable for situations without internet access or with restricted network connections. Follow the steps below to import the official activation package to activate the software.

① Open the software and select "Offline Activation" in the activation pop-up window.

② Click on "Device Code," copy the generated device code, and send it to our official customer support to obtain the activation package.

③ Download the activation package, click the import icon on the right side of the activation window and import the package, then click "Activate."

Note: If activation fails, please contact our official customer support for assistance.

¶ 1. File

¶ 1.1 Data Import

¶ 1.1.1 New Measurement

Method 1: Click "New Measurement" on the homepage to create a new measurement and enter the measurement interface.

Method 2: When it's required to end the current measurement and create a new project, click "New" in the navigation bar to create a new file for measurement.

¶ 1.1.2 Scan Data Import

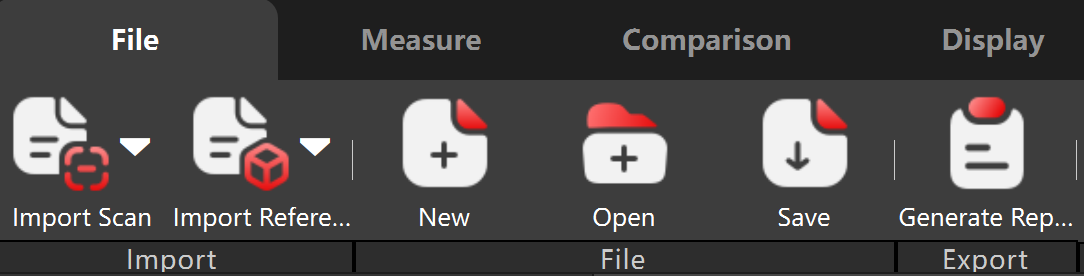

Click "Import Scan" in the navigation bar, select model type in the drop-down menu and import the scan data for measurement.

Supported file formats:

Point Cloud Formats: *.ply, *.pts, *.xyz, *.asc, *.txt, *.csv

When importing text point cloud files in formats such as *.xyz, *.txt, or *.csv, the software will automatically open the pop-up window of "Input Parameters." Click here for details.

Mesh Formats: *.stl, *.obj, *.ply

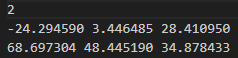

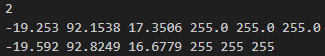

Note: The current software version supports *.pts file format with the following requirements (continuously optimized in the later versions).

① The file header contains only the total number of points.

② The file consists of either three columns of point cloud data (X, Y, Z), or six columns (X, Y, Z, R, G, B). In the six-column format, the first three columns represent the spatial coordinates of the points and the last three columns represent the RGB color information. For example:

¶ 1.1.3 Reference Data Import

Click "Import Reference" in the navigation bar, select model type in the drop-down menu and import the CAD Model or other reference data for comparison.

Supported File Formats:

CAD Formats: *.stp (It includes complete entity geometric feature information, such as: CYLINDRICAL_SURFACE, SPHERICAL_SURFACE, CONICAL_SURFACE, PLANE, CIRCLE, etc.)

Mesh Formats: *.stl, *.obj, *.ply

¶ 1.1.4 Reference Data Replacement

Reclick "Import Reference" and a pop-up window titled "Replace Reference Data" will appear. Select “Ok” to replace the reference data.

¶ 1.2 Project Operation

¶ 1.2.1 Open a Project

Method 1: Click the Open File button on the Home page to open the measurement files (*.revoMeasure files) saved in the local folder.

Method 2: Click the Open button in the navigation bar to open the measurement files (*.revoMeasure files) saved on the local folder for view or measurement.

¶ 1.2.2 Save a Project

Click the Save button in the navigation bar to save the current measurement file (*.revoMeasure files) to the local folder for view or measurement.

¶ 1.3 Export Report

The report involves the model overview, the created features, as well as the measurement and comparison results.

- Applications:

① Fully displays the model detection result, enabling users to better evaluate model's performance and quality.

② Records the detailed model detection process, allowing for easy review, and comparison between the multiple versions of detection results.

- How to export a report:

① Click the Generate Report button in the top navigation bar.

② In the pop-up window, fill in the project information, such as project name, part name, inspector, etc.

③ Select the wanted project on the right side of the window.

④ Confirm or change the save path.

⑤ Click Export to save the report as a PDF.

¶ 2. Measure

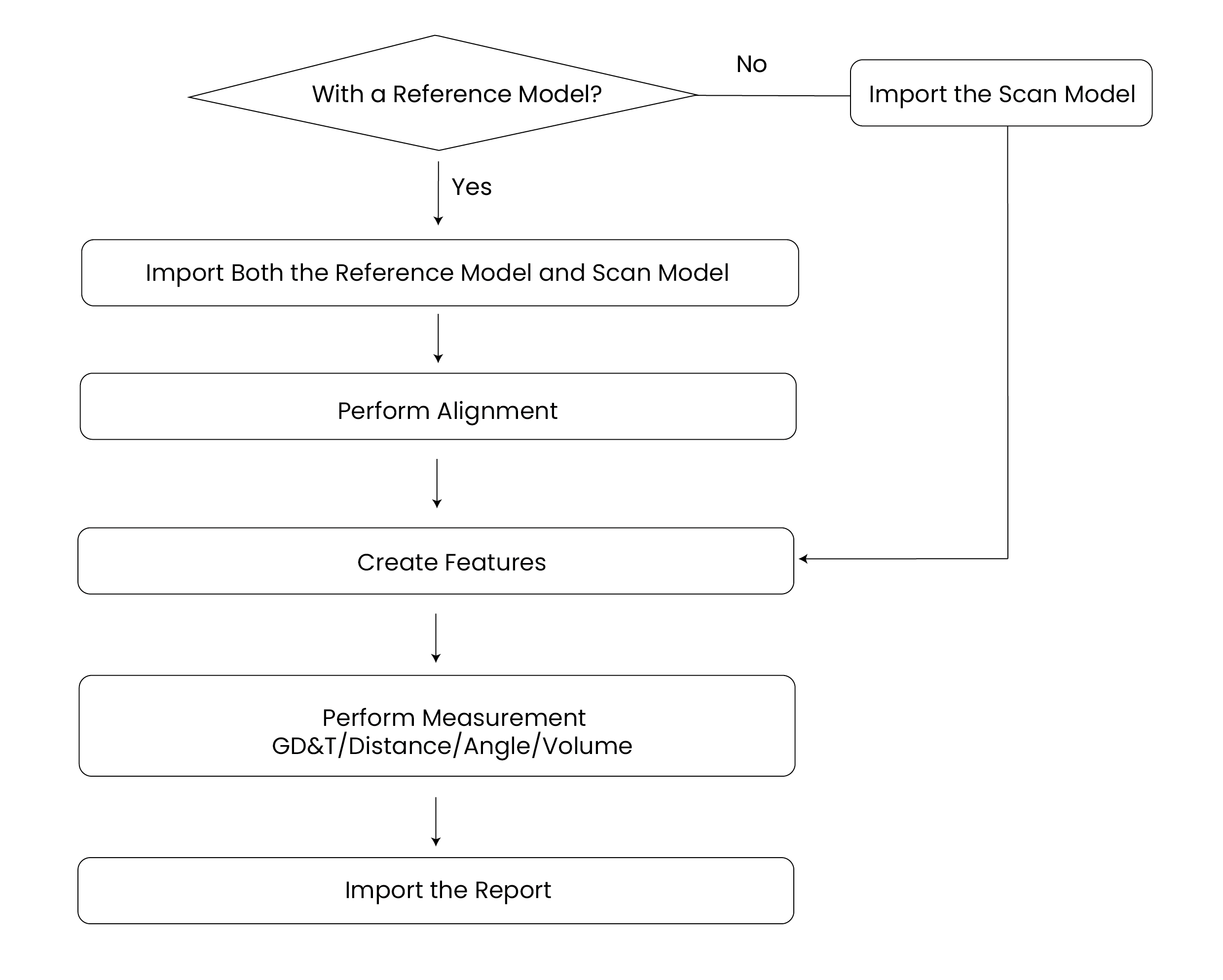

The measurement workflow is as follows:

¶ 2.1 Create Features

¶ 2.1.1 Overview

The software supports to create geometric features, such as point, straight line, plane, circle, cylinder, sphere (Click to jump to the corresponding chapter).

When creating a plane feature, circle feature, cylinder feature or sphere feature, advanced settings are available to acquire more accurate results:

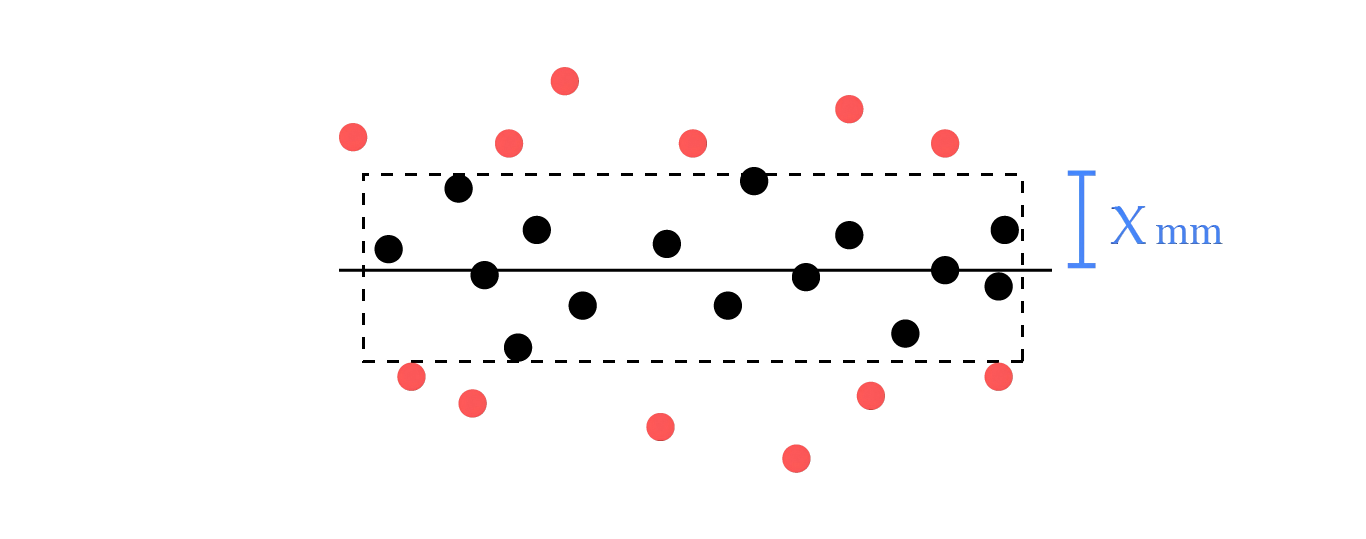

A parameter used to define the tolerance of the Pick-and-Fit method. After defining an approximate feature by picking points, any elements whose distance from the approximate feature exceeds the specified maximum value will be discarded to accelerate the fitting process.

Note: In the illustration, black points are included in the fitting process, while red points are filtered out.

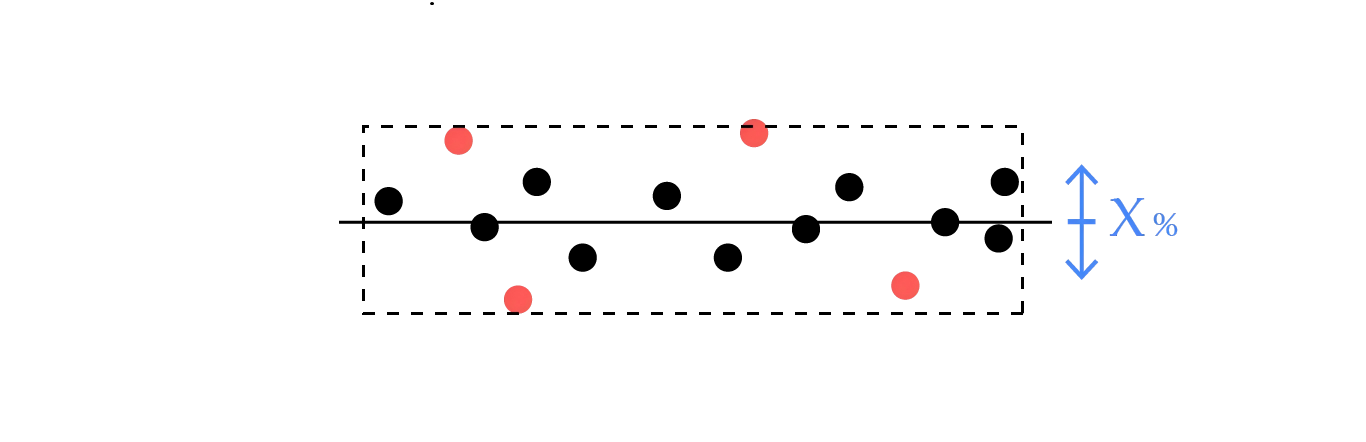

The point sampling percentage defines the proportion of scanned data retained after outlier removal. A higher value keeps more points (fewer outliers removed), while a lower value may remove too many valid data points, infuencing the fitting accuracy.

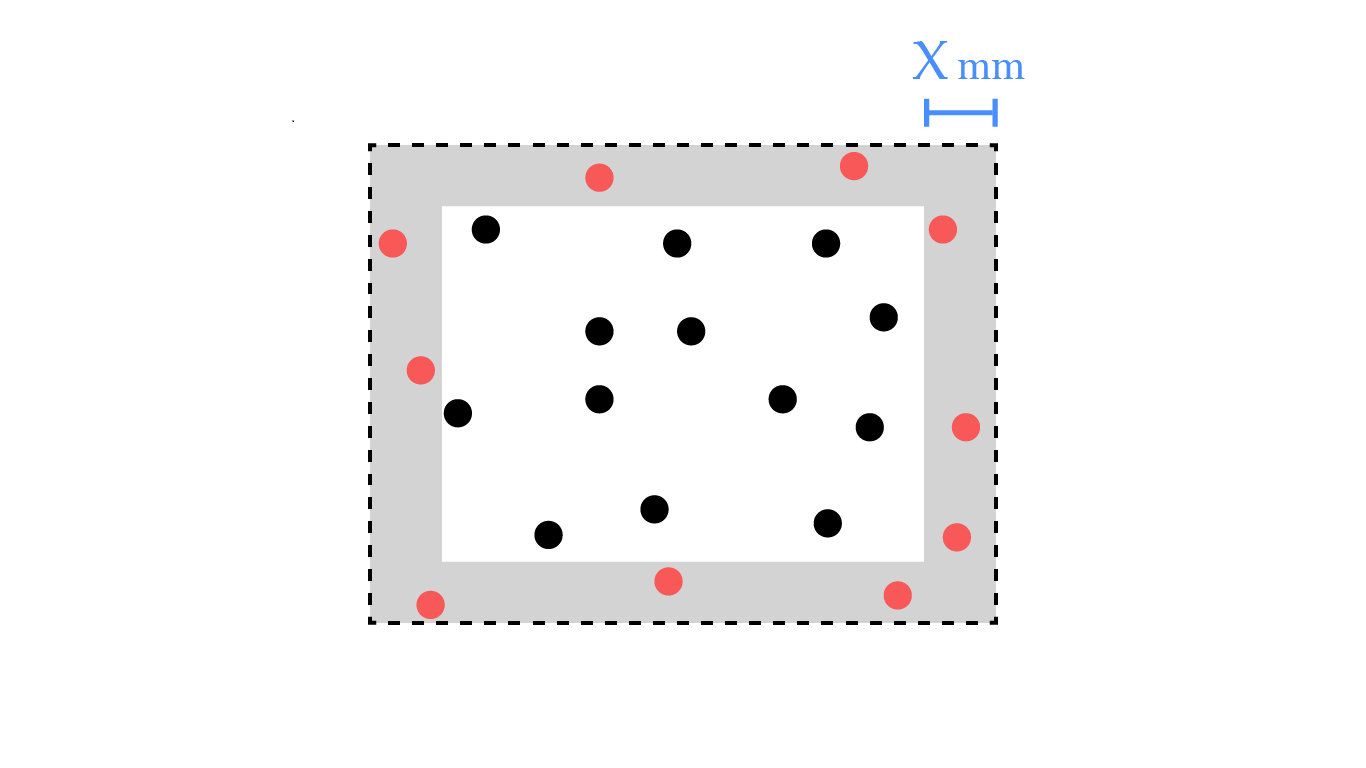

Note: In the illustration, black points represent the data included in the fitting within the boundary exclusion distance, while red points represent the data excluded from the fitting due to exceeding the distance threshold.

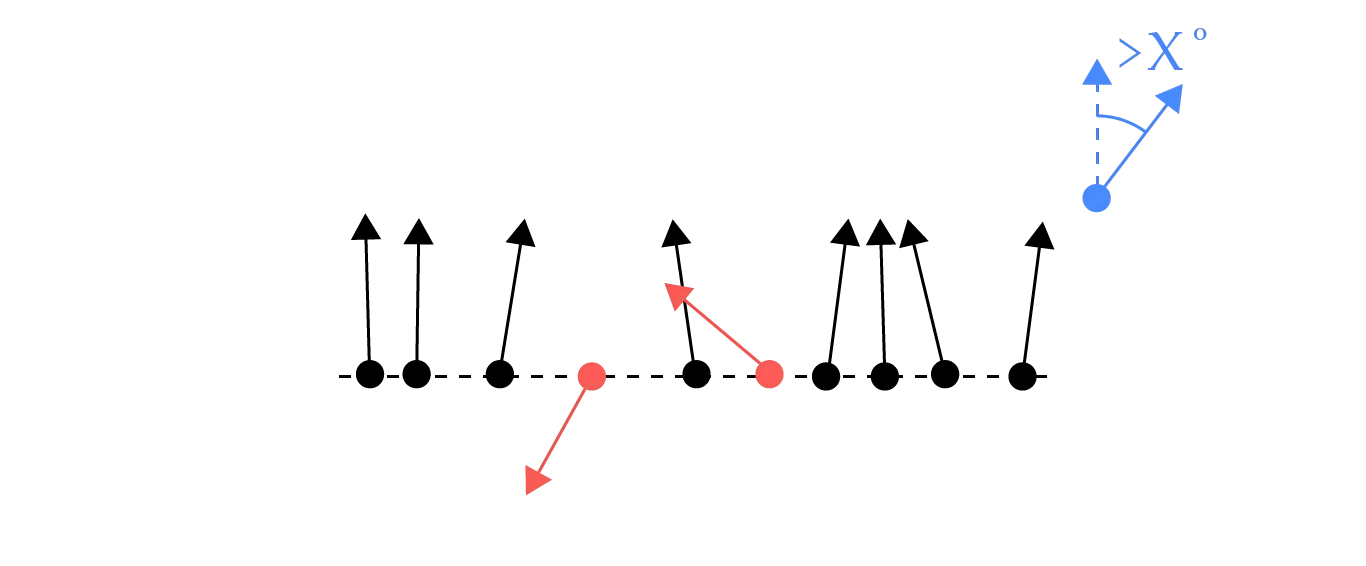

This parameter is used to exclude points belonging to surface regions that are irrelevant to the feature being fitted. When this parameter is enabled, the system specifies the maximum angle between the normal vector of a data point and the normal vector of the nearest feature point. This angle is used for filtering. The valid range is 0°to 180°(inclusive).

Note: In the illustration, black points are included in the fitting process, while red points are filtered out.

The point sampling percentage defines the proportion of scanned data retained after outlier removal. A higher value keeps more points (fewer outliers removed), while a lower value may remove too many valid data points, infuencing the fitting accuracy.

Note: In the illustration, black points are included in the fitting process, while red points are filtered out.

¶ 2.1.2 Point

A point feature is used to mark a certain location on the model's surface. It can only be created manually. Create it by selecting one of the following methods in Selection Mode.

Method 1: Fit by Selected Points

① Double-click a location on the model's surface to define a point.

② Click the "Create" button to complete the creation.

Method 2: Input Coordinates

① Enter the existing coordinates.

② Click the "Create" button to complete the creation.

Method 3: Auxiliary Objects

① Select a feature on the reference object. Available reference features include Circle and Sphere. Refer to the section 2.1.5/2.1.7 for how to create a circle or a sphere.

② Select the created reference feature.

③ Click the "Create" button to complete the creation.

¶ 2.1.3 Straight Line

A straight line feature is a virtual axis with direction and length. It can only be created manually. Create it by selecting one of the following methods in Selection Mode.

Applications:

① Locate the axis of the target object.

② Find the intersection line of two intersecting planes or lines.

③ Calculate the average line of two lines.

④ Inspect and measure the straightness of a line feature or axis.

Method 1: Fit by Selected Points

① Double-click and select two points on the model's surface to define a straight line.

② Click the "Create" button to complete the creation.

Method 2: Input Coordinates

① Define a straight line by entering the origin coordinates, direction, and length of the line.

② Click the "Create" button to complete the creation.

Method 3: Auxiliary Objects

Note: Ensure the needed reference features are created before using the sub methods below. Refer to the section 2.1 for how to create needed features.

Sub-method 1: Line from Angle Bisector of Coplanar Lines

① Select two coplanar auxiliary lines.

② Click the "Create" button to complete the creation.

Sub-method 2: Line from Average of Two Lines

① Select two auxiliary lines.

② Click the "Create" button to complete the creation.

Sub-method 3: Line from Two Circle Centers

① Select two auxiliary circles; the center of the circle 1 will be set as the origin.

② Click the "Create" button to complete the creation.

Sub-method 4: Line from Cylinder Axis

① Select an auxiliary cylinder.The axis of the cylinder will be created as a line feature, with the direction of the line feature along the cylinder axis.

② Click the "Create" button to complete the creation.

Sub-method 5: Line from Point Normal to Plane

① Select an auxiliary point feature and an auxiliary plane feature. Set the point as the origin, and create a line along the point normal to plane.

② Click the "Create" button to complete the creation.

Sub-method 6: Line from Intersection of Two Planes

① Select two non-parallel auxiliary planes. A line will be created along the intersection of the two planes.

② Click the "Create" button to complete the creation.

Sub-method 7: Projection Line from Line to Plane

① Select a line and a plane that are not perpendicular to each other. The projection from the line to the plane will be created as a line.

② Click the "Create" button to complete the creation.

Sub-method 8: Line from Two Point Features

① Select two point features. Then, connect the two points to create a line with its direction running from the first selected point to the second one.

② Click the "create" button to complete the creation.

¶ 2.1.4 Plane

A plane feature is a virtual plane with definite normal direction but infinite size.

Method 1: Create from CAD

① Click Import Reference and import a CAD file.

② Click Comparison to use Automatic Alignment or Manual Alignment.

③ Click the "Plane" button in the Create Feature tab bar, and move the mouse over the CAD model to define a plane.

④ Click the "Create" button to complete the creation.

Method 2: Smart Fit

① Click the "Plane" button in the Create Feature tab bar, then select Smart Fit in the Selection Mode.

② Select tools such as Brush Select or Rectangle according to the model state.

③ Select an area on the model surface where the plane is to be fitted using the selections tools. The software will automatically extract the plane where the selected area is.

- Smart Extended Recognition: When enabled, it automatically expands the analysis from the selected data to surrounding data, fitting features based on the complete dataset. When disabled, only the selected data is used to fit features.

- Add / Delete Selection Area: Select "Add Selection Area" to continuously add selected areas; Select "Delete Selection Area" to continuously delete unwanted areas.

- Area Range: Typically used to exclude low-quality scan data at model boundaries, selecting more accurate point cloud data for feature fitting. Click "Expansion" to enlarge the selected area, or click "Contraction" to reduce the selected area.

- Expansion / Contraction Strength: Used together with Area Range. A larger strength value results in a greater expansion or contraction per operation, while a smaller value provides finer adjustments.

④ Click the "Create" button to complete the creation.

Method 3: Fit by Selected Points

① Double-click the desired locations and select 3 points to define a plane.

② Click the "Create" button to complete the creation.

¶ 2.1.5 Circle

A circle feature is a 2D entity defined by a center point and a radius.

Method 1: Create from CAD

① Click Import Reference to import a CAD file.

② ② Click Comparison to use Automatic Alignment or Manual Alignment.

③ Click the "Circle" button in the Create Feature tab bar, and move the mouse over the CAD model to define a circle.

④ Click the "Create" button to complete the creation.

Method 2: Smart Fit

① Click the "Circle" button in the Create Feature tab bar, then select Smart Fit in the Selection Mode.

② Select tools such as Brush Select or Rectangle according to the model state.

③ Select an area on the model surface where the circle is to be fitted using the selections tools. The software will automatically extract the circle where the selected area is.

④ Click the "Create" button to complete the creation.

Method 3: Fit by Selected Points

① Double-click the desired locations and select 3 points to define a circle.

② Click the "Create" button to complete the creation.

¶ 2.1.6 Cylinder

Method 1: Create from CAD

① Click Import Reference to import a CAD file.

② Click Comparison to use Automatic Alignment or Manual Alignment.

③ Click the "Cylinder" button in the Create Feature tab bar, and move the mouse over the CAD model to define a cylinder.

④ The software will automatically extract the cylinder where the selected area is.

Method 2: Smart Fit

① Click the "Cylinder" button in the Create Feature tab bar, then select Smart Fit in the Selection Mode.

② Select tools such as Brush Select or Rectangle according to the model state.

③ Select an area on the model surface where the cylinder is to be fitted using the selections tools. The software will automatically extract the cylinder where the selected area is.

The following parameters are available for efficiently selecting the data with the selection tools:

- Penetrate: When it is enabled, all the point cloud data along the current view direction (including the hided data) will be selected; When disabled, only visible points are selected.

- Smart Extended Recognition: When enabled, it automatically expands the analysis from the selected data to surrounding data, fitting features based on the complete dataset. When disabled, only the selected data is used to fit features.

- Add / Delete Selection Area Select "Add Selection Area" to continuously add selected areas; Select "Delete Selection Area" to continuously delete unwanted areas.

- Area Range: Typically used to exclude low-quality scan data at model boundaries, selecting more accurate point cloud data for feature fitting. Click "Expansion" to enlarge the selected area, or click "Contraction" to reduce the selected area.

- Expansion / Contraction Strength: Used together with Area Range. A larger strength value results in a greater expansion or contraction per operation, while a smaller value provides finer adjustments.

④ Click the "Create" button to complete the creation.

Method 3: Fit by Selected Points

① Double-click the desired locations and select 4 points. The first three ones will create a circle, and the fourth one defines the cylinder's normal direction and height.

② Click the "Create" button to complete the creation.

Method 4: Input Coordinates

① Input the coordinates (x,y,z) at the cylinder's bottom center, axis direction(i,j,k), radius and height to define a cylinder.

② Click the "Create" button to complete the creation.

¶ 2.1.7 Sphere

Method 1: Create from CAD

① Click Import Reference to import a CAD file.

② Click Comparison to use Automatic Alignment or Manual Alignment.

③ Click the "Sphere" button in the Create Feature tab bar, and move the mouse over the CAD model to define a sphere.

④ Click the "Create" button to complete the creation.

Method 2: Smart Fit

① Click the "Sphere" button in the Create Feature tab bar, then select Smart Fit in the Selection Mode.

② Select tools such as Brush Select or Rectangle according to the model state.

③ Select an area on the model surface where the sphere is to be fitted using the selections tools. Options include Entire Sphere, Convex Hemisphere, and Concave Hemisphere. The software will automatically extract the sphere where the selected area is.

The following parameters are available for efficiently selecting the data with the selection tools:

- Penetrate: When it is enabled, all the point cloud data along the current view direction (including the hided data) will be selected; When disabled, only visible points are selected.

- Smart Extended Recognition: When enabled, it automatically expands the analysis from the selected data to surrounding data, fitting features based on the complete dataset. When disabled, only the selected data is used to fit features.

- Add / Delete Selection Area: Select "Add Selection Area" to continuously add selected areas; Select "Delete Selection Area" to continuously delete unwanted areas.

- Area Range: Typically used to exclude low-quality scan data at model boundaries, selecting more accurate point cloud data for feature fitting. Click "Expansion" to enlarge the selected area, or click "Contraction" to reduce the selected area.

- Expansion / Contraction Strength: Used together with Area Range. A larger strength value results in a greater expansion or contraction per operation, while a smaller value provides finer adjustments.

④ Click the Create button to complete the creation.

Method 3: Fit by Selected Points

① In a 3D view, double-click a sphere's surface and select four points.

② Click the "Create" button to complete the creation.

¶ 2.2 GD&T

¶ 2.2.1 Overview

The GD&T (Geometric Dimensioning and Tolerancing) supports tolerance evaluation based on scan data, covering a range of features including circularity, flatness, straightness, cylindricity, concentricity, true position, parallelism, perpendicularity, angularity, circular runout, total runout (Click to jump to the corresponding chapter).

Before GD&T measurement, ensure the needed features are created.

¶ 2.2.2 Datum

In GD & T, a datum is required for all geometric tolerances (except for form tolerances) before calculation. To set a datum, select it from the dropdown menu.

How to set a datum?

① Select a feature from the object tree, and right-click to set it as a datum. Then, the corresponding node’s properties and name in the object tree will be automatically updated.

② click "Datum" in the GD&T Tab bar, select and rename the feature to be defined as a datum, then click "Create."

The datums (labeled A to Z) totalled 23. If more than 23 datums are needed in a single measurement, they should be renamed.

¶ 2.2.3 Circularity

Circularity evaluates the form deviation of a cross-sectional profile from a perfect circle.

Method 1:

Click Measurement in the top navigation bar, and select GD & T - Circularity.Then, select the desired circle using one of the following methods:

① Click the label of the desired circle in the main viewport. (coming soon)

② Click the desired circle in the object tree.

③ Select the desired circle from the dropdown menu of Feature Measurement on the right side.

After selecting the desired circle, click Measure on the right bottom corner, and the label indicating the result will appear on the selected circle.

Method 2: (coming soon)

Select the desired circle from the object tree, or select its label in the main window. Then, right-click to open the menu, and chooseGD & T - Circularity for measurement.

¶ 2.2.4 Flatness

Flatness evaluates the form deviation of a surface from an ideal plane.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Flatness for measurement.

The following three ways are available to select a plane:

① Click the label of the desired plane in the main viewport. (coming soon)

② Click the desired plane feature in the object tree. (coming soon)

③ Select the desired plane from the dropdown menu of Feature Measurement on the right side.

Click Measure, and the label indicating the result will appear on the selected plane. If the target plane is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired plane from the object tree, or choose its label in the main window. Then, right-click to open the menu, and select GD&T - Flatness for measurement.

¶ 2.2.5 Straightness

Straightness evaluates the form deviation of a line feature or an axis feature.

Straightness measurement is applied to the fitted lines or the lines extracted from the cylinder axis.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Straightness for measurement.

The following three ways are available to select a straight line: When selecting a cylinder, the measured line is the line along with the cylinder's axis.

① Click the labels of the desired straight line or cylinder in the main viewport. (coming soon)

② Click the desired straight line or cylinder in the object tree. (coming soon)

③ Select the straight line or cylinder from the dropdown menu of Feature Measurement on the right side. (coming soon)

Note: When selecting a cylindrical feature, the measured line is the axis extracted from the cylinder.

Click Measure, and the label indicating the result will appear on the selected straight line. If the target straight line is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired straight line from the object tree, or choose its label in the main window. Then, right-click to open the menu, and select GD&T - Straightness for measurement.

¶ 2.2.6 Cylindricity

Cylindricity evaluates the form deviation of a cylindrical surface from a perfect cylinder.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Cylindricity for measurement.

The following three ways are available to select a cylinder:

① Click the label of the desired cylinder in the main viewport. (coming soon)

② Click the target cylinder from the object tree. (coming soon)

③ Select the target cylinder from the dropdown menu of Feature Measurement on the right side.

Click Measure, and the label indicating the result will appear on the selected cylinder. If the target cylinder is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the target cylinder from the object tree, or choose its label in the main window. Then, right-click and choose GD & T - Cylindricity for measurement.

¶ 2.2.7 Concentricity

Concentricity describes the deviation of a feature’s central axis or center point from being perfectly aligned with a specified datum.

Concentricity measurement is applicable to:

① The feature with a center point, like a circle or a sphere.

② The feature with a central axis, like a cylinder.

When selecting the feature with a central axis, concentricity is also referred to as coaxiality.

The concentricity measurement is also based on a datum. Being concentric or coaxial with the measured object, the established datum should not be a point or a sphere. For example, when measuring a feature's coaxiality, the selected datum should also be a feature with a central axis. Refer to Section 2.2.2 for how to set up a datum.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Concentricity for measurement.

The following three ways are available to select the feature to be measured:

① Click the labels of the desired circle, sphere, or cylinder in the main viewport. (coming soon)

② Click the desired circle, sphere, or cylinder in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to create it in the object tree.

Click Measure, and the label indicating th result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - Concentricity for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.2.8 True Position

True Position is used to describe the positional deviation of a feature from a datum.

The True Position measurement is based on one or more datums. Refer to Section 2.2.2 for how to set up a datum.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - True Position for measurement.

There are three ways to select a measured feature:

① Click the label of the desired feature in the main viewport. (coming soon)

② Click the target feature in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

Click Measure, and the label indicating True Position result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - True Position for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.2.9 Parallelism

Parallelism is used to describe the deviation in the parallel relationship between a feature and a specified datum plane or datum axis.

Parallelism measurement applies to several types of feature combinations, such as plane-to-plane, plane-to-line, line-to-plane, and line-to-line, in which the "plane" includes plane and circle features, and the "line" includes straight lines and cylinder axes. Parallelism measurement is based on a datum. Refer to Section 2.2.2 for how to set up a datum.

Note: The feature and the datum for parallelism measurement must be in a parallel relationship; otherwise, parallelism cannot be measured.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Parallelism for measurement.

There are three ways to select a measured feature:

① Click the label of the desired feature in the main viewport. (coming soon)

② Click the desired feature in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

Click Measure, and the label indicating Parallelism result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - Parallelism for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.2.10 Perpendicularity

Perpendicularity is used to describe the deviation in the perpendicular relationship between a feature and a specified datum plane or axis.

Perpendicularity measurement applies to several types of feature combinations, such as plane-to-plane, plane-to-line, line-to-plane, and line-to-line, in which the "plane" includes plane and circle, and the "line" includes straight lines and cylinder axes. Perpendicularity measurement is based on a datum. Refer to Section 2.2.2 for how to set up a datum.

Note: The feature and the datum for perpendicularity measurement must be in a perpendicular relationship. Otherwise, perpendicularity cannot be measured.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Perpendicularity for measurement.

There are three ways to select the measured feature:

① Click the label of the desired feature in the main viewport. (coming soon)

② Click the desired feature in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

Click Measure, and the label indicating Perpendicularity result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - Perpendicularity for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.2.11 Angularity

Angularity is used to describe the deviation of a feature from a specified datum when the relationship is at a specified angle (0° < θ < 90°).

Angularity measurement applies to several types of feature combinations, such as plane-to-plane, plane-to-line, line-to-plane, and line-to-line, in which the "plane" includes plane and circle, and the "line" includes straight lines and cylinder axes. Angularity measurement is based on a datum. Refer to Section 2.2.2 for how to set up a datum.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Angularity for measurement.

There are three ways to select the measured feature:

① Click the label of the desired feature in the main viewport. (coming soon)

② Click the desired feature in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

Manually set the angle value (or acquire the value from the CAD model), click Measure, and the label indicating Angularity result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - Angularity for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.2.12 Circular Runout

Circular runout is used to describe the deviation of a cross-section formed by a cylindrical or conical surface and its datum axis. It includes radial and axial circular runout.

Currently, circular runout measurement only applies to the circle features on the exposed end of a cylinder's surface.

Circular Runout measurement is based on a datum. Refer to Section 2.2.2 for how to set up a datum.

The datum can be a cylinder or a line generated from the axis of the cylinder. When selecting a cylinder feature, its axis is used as the datum.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Circular Runout. Select Radial or axial on the right side for measurement.

There are three ways to select the measured feature:

① Click the label of the desired feature in the main viewport. (coming soon)

② Click the desired feature in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

Click Measure, and the label indicating Circular Runout result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - Circular Runout for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.2.13 Total Runout

Total runout is used to describe the deviation of a rotational surface formed by a cylindrical or conical feature relative to its datum axis. It includes radial and axial total runout. The total runout measurement only applies to cylinder features.

Total Runout measurement is based on a datum. Refer to Section 2.2.2 for how to set up a datum.

The datum can be a cylinder or a line generated from the axis of the cylinder. When selecting a cylinder feature, its axis is used as the datum.

Measurement Method 1:

Click Measure in the top navigation bar, and select GD & T - Total Runout. Select Radial or axial on the right side for measurement.

There are three ways to select the measured feature:

① Click the label of the desired feature in the main viewport. (coming soon)

② Click the desired feature in the object tree. (coming soon)

③ Select the desired feature from the dropdown menu of Feature Measurement on the right side.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

Click Measure, and the label indicating Total Runout result will appear on the selected feature. If the desired feature or datum is not created, click Create New Feature to create it before measurement.

Measurement Method 2: (coming soon)

Select the desired feature from the object tree, or select its label in the main window. Then, right-click to open the menu, and select GD & T - Total Runout for measurement.

Select the existing datum from the datum selection dropdown list. If the datum is not created, refer to Section 2.2.2 to set it up in the object tree.

¶ 2.3 Basic Measurement

¶ 2.3.1 Distance Measurement

Measures the distance between the selected features.

Distance measurement applies to various types of geometric features, including point-to-point, point-to-line, line-to-line, line-to-plane, and plane-to-plane.

If only scan data is available, the measurement result is presented as the actual value derived from the scan data.

If reference data is available and aligned with the scan data, the measurement results are presented as reference distance, the scanned distance, and the deviation between the two.

Tolerance constraints can also be applied to the deviation results.

¶ 2.3.1.1 Point to Point

Measures the distance from point to point.

Point-to-point distances not only applies to two points, but also to two circle centers or two sphere centers.

¶ 2.3.1.2 Point to Line

Measures the perpendicular distance from a point to its extended line.

Available point features include: point, circle (center), and sphere (center).

Available line features include: line and cylinder (axis).

¶ 2.3.1.3 Line to Line

Measures the spatial distance between two lines.

When the lines are skew (non-coplanar), the distance is the length of the segment perpendicular to both lines.

When the lines are coplanar, the distance is the length of a perpendicular from the midpoint of object 1 to the extended line of object 2.

The line-to-line distance measurement is only applicable to line features. If the axis measurement for a solid feature is required, create the axis as a line feature first.

Some quick operations are supported: For example, when the cylinder axis measurement is required, select a cylinder feature.

¶ 2.3.1.4 Line to Plane

Measures the distance from the midpoint of a line to an infinite plane.

When the midpoint of the line lies on the plane (or the line lies on the plane), the distance is 0.

¶ 2.3.1.5 Plane to Plane

Measures the distance between two parallel planes.

If the planes are unparallel, the distance is 0.

The plane-to-plane distance measurement is only applicable to plane features. If the measurement for a solid feature's surface is required, create the surface as a plane feature first.

¶ 2.3.2 Angle Measurement

Measures the angle between the selected features.

Angle Measurement is applicable to line-to-line, line-to-plane, and plane-to-plane.

Available line features include: line and cylinder (axis).

Available plane feature is plane.

¶ 2.3.2.1 Line to Line

Measures the angle between two lines. The software will automatically project the feature 1 to the feature 2 by moving feature 1's parallel line to feature 2's coplane, and the included angle is calculated as the line to line angle.

¶ 2.3.2.2 Line to Plane

Measures the angle between a line to a plane. Calculate the angle between their normal vectors, and the complementary angle is the measurement result.

¶ 2.3.2.3 Plane to Plane

Measures the angle between two planes. Calculate the angle between their normal vectors, and the acute angle or right angle is the measurement result.

¶ 2.3.3 Volume Measurement

Measures the overall volume of the scanning model(meshed model).

Steps:

① In the Basic Measurement tab, select Volume.

② Choose Overall Volume.

③ Click "Calculate", and the result will appear in both the label and the object tree.

Notes:

It should be a meshed model. If the model isn't selected through, the result displays the volume of the bounding box.

The volume calculation of a non-watertight model is for reference only.

¶ 3. Comparison

¶ 3.1 Alignment

¶ 3.1.1 Automatic Alignment

The software provides automatic alignment between models. When reference data is imported, the alignment will be performed automatically.

Automatic alignment applies to feature-rich objects. Repeat the operation until getting a better result.

Automatic alignment is not available to models with no normal, which needs to be aligned via Multi-point Alignment.

Follow the steps below if an alignment is required in other scenarios:

① Ensure both the reference data and scan data have been imported.

② Click Comparison in the navigation bar, and select Automatic Alignment.

¶ 3.1.2 Multi-point Alignment

The multi-point alignment is fit for the scenario where the object features are hard to be identified by automatic alignment.

Steps:

① Ensure both the reference model and scan model have been imported.

② Click Comparison in the navigation bar,and select Multi-point Alignment.

③ Select at least 3 pairs of points on the same locations of the two models. Note that the 3 pairs of points should be located on multiple surfaces.

④ In the operation panel on the right side, check the number of the points on the two models and how they are matched.

⑤ Click the Align button at the bottom of the right panel to complete alignment.

Note: For more accurate alignment, it is recommended to select points on multiple surfaces (e.g., front, back, and side), particularly vertices or edge points.

¶ 3.2 Deviation Analysis

Deviation analysis is generally used for deformation analysis during the manufacturing process. The software supports both Overall Deviation and Point DeviationAnalysis.

¶ 3.2.1 Overall Deviation

Overall deviation aims to analyze the deviation between the scan model and the reference model by projecting all paired points on the scan model to the reference model. The result will be rendered as color map on the scan model, helping analyze both positive and negative deviations across the entire model. The color map supports to set the tolerance range and its colors, providing clearer deviation analysis results.

Steps:

① Ensure both the reference data and scan data have been imported and aligned.

② Click Comparison, then select Overall Deviation, and click Create.

Once calculation is complete, the result is displayed as a deviation color map on the scan model.

You can change the upper and lower limits of the color bar in the property page. Any deviation values beyond the limits will display the color of the limits.

¶ 3.2.2 Point Deviation

Point deviation is typically used to analyze deviations at specific points between the reference and scan data, helping control the key areas of the model.

Steps:

① Ensure both the reference model and scan model have been imported and aligned.

② Click Comparison,select Overall Deviation and calculate.

③ After calculating the overall deviation, select Point Deviation.

④ Each time a point is selected, the interface will display the corresponding color and a point deviation label.

⑤ By default, the color of the deviation label header is the same with the deviation result color which can be found in the color bar.

Additionally, Point Deviation can also be performed based on the Whole Deviation analysis.

¶ 4. Display

¶ 4.1 Render and Display

The Display option in the navigation bar offers multiple rendering modes for viewing meshed and CAD models, as well as various model display states.

¶ 4.1.1 Scan

Switch between the rendering modes of the mesh model in the viewport.

Three rendering modes are available: wireframe rendering, mesh rendering, vertex rendering.

Supports texture rendering and displaying and allows importing the texture files acquired by Revopoint scanners for viewing.

¶ 4.1.2 CAD

Switch between the rendering modes of the CAD model. The software offers three rendering modes: Solid Rendering, Wireframe Rendering, and Solid Wireframe Rendering.

¶ 4.2 View

¶ 4.2.1 Fit to View

Automatically zooms the view to fit the size of the model window, centering and optimally displaying all models.

¶ 4.2.2 Initial Pose

Reset the model to the initial location and pose when it's imported.

¶ 5. Shortcut Keys

¶ 5.1 Shortcut Keys

Multi-select: Hold Shift and click on multiple objects. Applicable in both the Object Tree and the Viewport.

Delete: Press the Delete key to delete the selected objects.

Move: Drag the mouse wheel. Or hold Shift key, and drag with the left mouse button.

Rotate: Hold the Ctrl key to rotate the model.

cancel: Esc

Zoom in/Zoom out the brush diameter: Hold the Ctrl key and scroll the mouse wheel.

Undo/Redo: Ctrl + Z/Ctrl + Y

¶ 5.2 Shortcut Operation

① In the Object Tree or Viewport, right-click a single selected feature to open a context menu. You can perform related operations, including Set as Datum, View Feature Properties, GD&T, Rename, Delete, Show/Hide, or Focus in Viewport.

② Select two features in the Object Tree, right-click to open the context menu. You can perform operations on both objects, including Measurement, GD&T, Delete, and Show/Hide.

③ Select multiple features or results in the Object Tree, right-click to open the context menu. You can perform batch operations such as Delete and Show/Hide.

④ Select multiple features or results in the Viewport, right-click to open the context menu. You can perform batch operations such as Delete and Show/Hide.

¶ 6. Glossary

| Measurement | GD&T | Geometric Dimensioning and Tolerancing |

| Straightness | The form error of a straight line feature or an axis feature. | |

| Flatness | The form error of a plane feature. | |

| Roundness | The form error of a circle feature and its cross-sectional circle. | |

| Cylindricity | The form error of a cylinder feature. | |

| Surface Profile | Deviation between an actual surface feature and its theoretically correct geometric shape. | |

| Parallelism | Error in the parallel relationship between a feature and a specified datum plane or axis. | |

| Perpendicularity | Error in the perpendicular relationship between a feature and a specified datum plane or axis. | |

| Angularity | Error in the angular relationship (0°<θ<90°) between a feature and the specified datum plane or axis. | |

| Concentricity | The concentricity or coaxiality error between a circle or axis feature and the specified datum. | |

| Symmetry | The deviation between the centers of two features and the datum center plane or center axis. | |

| True Position | The positional error of a feature relative to a datum. | |

| Circular Runout | Error between the cross-section of a cylindrical or conical feature and the ideal circle formed with respect to its datum axis. | |

| Radial Runout | Error between the surface of a cylindrical or conical feature and the ideal rotational surface formed with respect to its datum axis. | |

| Distance | Measures the length distance between two points or features. | |

| Angle | Measures the angular dimension between two features. | |

| Radial | Measurements or dimensions taken along the radius of a circle or cylinder feature. | |

| Surface Area | Measures the surface area of the specified feature or the selected region. | |

| Volume | Measures the overall volume of the meshed model. | |

| Create Section | Create a cross-section | |

| Thickness | Measures the thickness at various positions of the entire model. | |

| Comparison | Import Reference | Import reference files for comparison. Both meshed models and CAD models can be imported. |

| Flip Normals | Invert the overall surface normals of the CAD model. | |

| Mirror | Set the datum plane as the center of mirroring to generate a CAD model symmetrical to the datum plane, which will serve as new reference data. | |

| Automatic Alignment | Automatically overlay more scan data onto the reference data and align them using a best-fit algorithm. | |

| Multi-Point Alignment | Align the scan data with the reference data by manually selecting multiple corresponding points on both models. | |

| Datum Alignment | Align the scan data to the reference data by registering geometric feature groups. Typically used for further optimization after automatic alignment. | |

| Feature Alignment | Align the scan data to the reference data by registering the centers of geometric features or surface points. Typically used for further optimization after automatic alignment. | |

| 3-2-1 Alignment | Align the scan data to the reference data by registering a combination of planes, axes, and points. Typically used for further optimization after automatic alignment. | |

| Overall Deviation | Measure the overall deviation between the reference data and the scan data. The deviation results are presented in the form of a color map. | |

| Point Deviation | Measure the deviation at specified points and display the deviation values with a color map. | |

| Sectional Deviation | Measure the deviation of the created sections, presenting the results with a color map. | |

| Boundary Deviation | Measure the boundary line position deviation between the reference data and the scan data, displaying the results with a color map. This function is applicable only to thin-walled workpieces. | |

| Show/Hide Deviation Color Map | Show or hide the current measurement deviation color map. | |

| Deviation Map Settings | Customize parameters such as the map colors and value range. | |

| Feature Creation | Free Creation | Quickly create multiple features on a CAD model through identifying and selecting them. |

| Circle | Create a circle feature | |

| Point | Create a point feature | |

| Cylinder | Create a cylinder feature | |

| Plane | Create a plane feature | |

| Line | Create a line feature | |

| Sphere | Create a sphere feature | |

| File | Import Reference | Import reference files for comparison. Both meshed models and CAD models can be imported. |

| Import Scan | Import a scan file to start measurement. Both point cloud models and meshed models can be imported. | |

| New | Start a new measurement | |

| Open | Open the measurement file saved on the local drive | |

| Save | Save the current measurement file on the local drive | |

| Generate Report | Generate and save the measurement report on the local drive | |

| Export as Template | Save the current measurement process as a template | |

| Display | Mesh Rendering | Render a mesh model's polygons |

| Wireframe Rendering | Render a mesh model's wireframe | |

| Vertices Rendering | Render a mesh model's vertices | |

| Texture Rendering | Display a mesh model's texture | |

| Solid Rendering | Render CAD solids | |

| Solid Wireframe Rendering | Render CAD solids and wireframe | |

| Wireframe Rendering | Render a CAD model's wireframe | |

| Fit to View | Zoom the model to fit in the main view window | |

| Initial Pose | Reset the model to the initial location and pose when imported | |

| Orthographic View | Switch the model to orthographic view | |

| Show Selected Only | Display only the selected object's labels in the main view window | |

| Auto Arrange | Automatically arrange the positions of all labels in the main view window | |

| Other | Overall Deviation | Comprehensive evaluation of deviations between all measurement points in the scan model and the CAD model. Click the "Create" button to automatically generate results. Results will be displayed as a color map. After generating the overall deviation, use the point deviation function to view deviation data at specific locations. |

| CAD Creation | Move the mouse over the CAD model and click the desired features. Click "Create" to quickly create a feature. | |

| Point Deviation | Double-click to display the point deviation of the selected point. Continuous selection is supported. Click "Complete" to save all the deviation values. Double-click the point deviation option in the object tree or view it in the exported report. |

|

| Datum Setting | The specified feature for measurement reference. Right-click a feature in the object tree and select "Set as Datum" to define it as the datum feature. |